HYTORC offers productivity enhancing solutions for the wind industry

PROJECT AND SYSTEM CONSULTING

The Wind Industry is innovating quickly. Our experts have supported global design and dimensioning with their skills in bolting and engineering from the very beginning.

HYTORC Wind specialists have decades of experience and can help to proactively avoid common bolting challenges during the design phase. If you need special fixtures or advanced fastener solutions, rely on a HYTORC bolting specialist for the answer. Contact our productivity enhancement group and schedule a consultation.

Contact Us

OPERATIONS AND MAINTENANCE

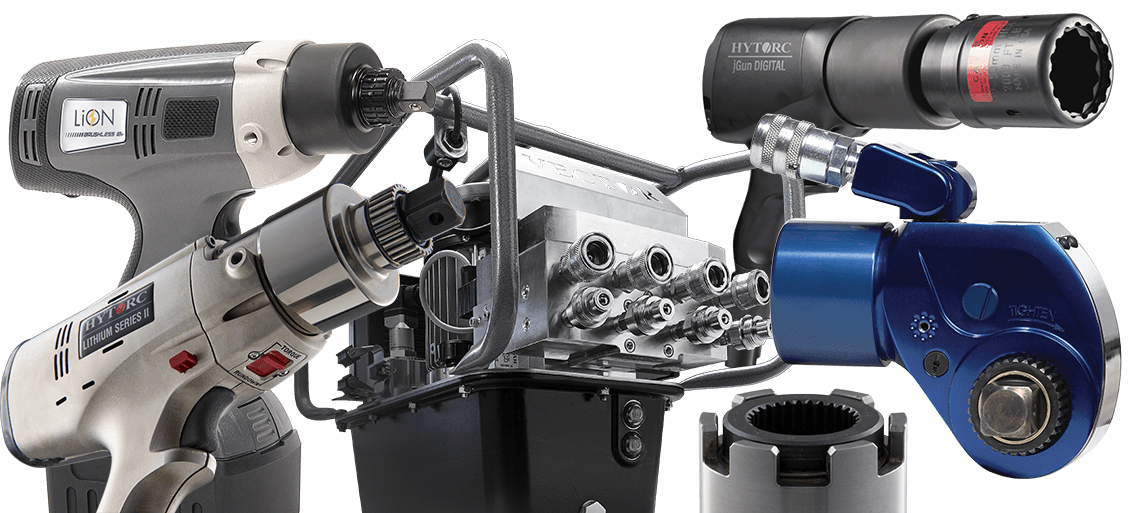

We understand the focus on lowering the cost of maintenance in the Wind Industry. That’s why HYTORC has developed tools, pumps, and fasteners to vastly reduce the time needed to complete these necessary operations.

Finding a loose bolt during maintenance can increase the number of torque checks required by ten times. That's why HYTORC has created the J-Washer which prevents loosening during vibration. This washer also eliminates the need for custom fixtures and reaction arms. The HYTORC Nut also simplifies tensioning procedures, reducing cost in the process.

Contact a Bolting Specialist for a free consultation and start reducing cost and improving performance today.

Contact UsOFFSHORE WIND

When it comes to offshore wind, the applications are larger and the stakes are higher. Regardless of the size of your application, HYTORC can provide a solution.

HYTORC has a variety of tools that can meet the higher torque requirements of offshore applications. With up to 5,000 ft. lbs (6779 Nm) the Lithium Series II Electric Tool features a long battery life and robust gearbox and housing.

Our lightweight hydraulic pumps are user-friendly and make it easier to work at heights, while still meeting power needs. The time is now to reduce your maintenance budget, contact our Wind Bolting Specialists for a free consultation.

Contact Us

TURBINE MANUFACTURING AND CONSTRUCTION

At HYTORC, we know that improving the speed and quality of Wind Turbine manufacturing is paramount. As these structures get bigger, the forces on the bolts and blade attachments also increase. As the leader in bolting technology, HYTORC has created the most robust tools and pumps in the wind industry.

When you purchase a HYTORC tool or pump, you will receive excellent training. Our mobile van techs can also provide calibration and repair services on-site. You’ll also receive free access to the HYTORC Connect App for electronic data capture with our electric tools.Contact a HYTORC Bolting Expert and remove uncertainty from your next project.

Contact Us

THE HYTORC

COMPLETE SOLUTION

24/7 SUPPORT

Your HYTORC relationship doesn’t end with the delivery of your tool.

HYTORC has live representatives available 24/7, 365 days a year. If

you need assistance, call us at

1-800-367-4986.

CERTIFIED TRAINING

We can provide bolting training on-site at a local HYTORC facility,

and we can also host OSHA-compliant training.

REGISTER HERE

CUSTOM ENGINEERING

We have a team dedicated to custom tools and reaction fixtures to help

improve efficiency and safety. A bolting specialist can work with you

to solve any wind design challenges.

LEARN MORE

ONSITE CALIBRATION AND REPAIR

Our mobile van technicians will come to you when time is crucial. They

can provide repairs and calibrations on-site and provide loaner tools

to keep your work going.

SCHEDULE

RENT TO OWN

Every tool rental earns credits towards the future purchase of HYTORC

products.

PROJECT AND SYSTEM CONSULTING

The Wind Industry is innovating quickly. Our experts have supported global design and dimensioning with their skills in bolting and engineering from the very beginning.

HYTORC Wind specialists have decades of experience and can help to proactively avoid common bolting challenges during the design phase. If you need special fixtures or advanced fastener solutions, rely on a HYTORC bolting specialist for the answer. Contact our productivity enhancement group and schedule a consultation.

Contact Us

OPERATIONS AND MAINTENANCE

We understand the focus on lowering the cost of maintenance in the Wind Industry. That’s why HYTORC has developed tools, pumps, and fasteners to vastly reduce the time needed to complete these necessary operations.

Finding a loose bolt during maintenance can increase the number of torque checks required by ten times. That's why HYTORC has created the J-Washer which prevents loosening during vibration. This washer also eliminates the need for custom fixtures and reaction arms. The HYTORC Nut also simplifies tensioning procedures, reducing cost in the process.

Contact a Bolting Specialist for a free consultation and start reducing cost and improving performance today.

Contact Us

OFFSHORE WIND

When it comes to offshore wind, the applications are larger and the stakes are higher. Regardless of the size of your application, HYTORC can provide a solution.

HYTORC has a variety of tools that can meet the higher torque requirements of offshore applications. With up to 5,000 ft. lbs (6779 Nm) the Lithium Series II Electric Tool features a long battery life and robust gearbox and housing.

Our lightweight hydraulic pumps are user-friendly and make it easier to work at heights, while still meeting power needs. The time is now to reduce your maintenance budget, contact our Wind Bolting Specialists for a free consultation.

Contact Us

TURBINE MANUFACTURING AND CONSTRUCTION

At HYTORC, we know that improving the speed and quality of Wind Turbine manufacturing is paramount. As these structures get bigger, the forces on the bolts and blade attachments also increase. As the leader in bolting technology, HYTORC has created the most robust tools and pumps in the wind industry.

When you purchase a HYTORC tool or pump, you will receive excellent training. Our mobile van techs can also provide calibration and repair services on-site. You’ll also receive free access to the HYTORC Connect App for electronic data capture with our electric tools.Contact a HYTORC Bolting Expert and remove uncertainty from your next project.

Contact Us

THE HYTORC

COMPLETE SOLUTION

24/7 SUPPORT

Your HYTORC relationship doesn’t end with the delivery of your tool.

HYTORC has live representatives available 24/7, 365 days a year. If

you need assistance, call us at

1-800-367-4986.

CERTIFIED TRAINING

We can provide bolting training on-site at a local HYTORC facility,

and we can also host OSHA-compliant training.

REGISTER HERE

CUSTOM ENGINEERING

We have a team dedicated to custom tools and reaction fixtures to help

improve efficiency and safety. A bolting specialist can work with you

to solve any wind design challenges.

LEARN MORE

ONSITE CALIBRATION AND REPAIR

Our mobile van technicians will come to you when time is crucial. They

can provide repairs and calibrations on-site and provide loaner tools

to keep your work going.

SCHEDULE

RENT TO OWN

Every tool rental earns credits towards the future purchase of HYTORC

products.

OUR PRODUCTS

English (United States)

English (United States)  Deutsch (Deutschland)

Deutsch (Deutschland)  简体中文(中国)

简体中文(中国)  Español (España)

Español (España)  English (South Africa)

English (South Africa)  English (Singapore)

English (Singapore)  Français (France)

Français (France)  English (Australia)

English (Australia)  English (United Kingdom)

English (United Kingdom)